Thinlays Asphalt Pavement Method

There is a new asphalt pavement method called thin-lift asphalt overlays namely Thinlays that recently become popular, especially in the pavement preservation. The reason is Thinlays have the ability to provide improved ride quality, reduce pavement distresses, maintain surface geometrics, reduce noise levels, reduce life-cycle costs, and provide long-lasting service.

There is a new asphalt pavement method called thin-lift asphalt overlays namely Thinlays that recently become popular, especially in the pavement preservation. The reason is Thinlays have the ability to provide improved ride quality, reduce pavement distresses, maintain surface geometrics, reduce noise levels, reduce life-cycle costs, and provide long-lasting service.

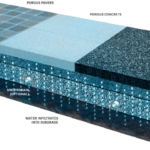

Asphalt thinlays, which range from 3/4-inch to 1-inch thick, are created with smaller nominal maximum aggregate sizes than typical asphalt pavement and are supplemented with more asphalt binder mix that is formulated to be softer. That helps make the mix more durable and resistant to cracking—ideal attributes for a preservation product.

As the demand for Thinlays grow because dwindling budgets and the uncertainty about the Highway Trust Fund have caused departments of transportation and municipalities to take longer looks at pavement preservation techniques. In light of this, more transportation entities are looking at thin overlays—commonly called thinlays—as a way to rehabilitate roads rather than replace them. The biggest factor contributing to the growth of Thinlay application is the increasing need for effective pavement preservation techniques. The additional challenges of aging roadways coupled with long-term budget reductions have taken their toll on pavement managers, causing them to seek better preservation solutions.

While Thinlay use is growing, there also is some trepidation because of some cases of misuse, cases that lead to mixed results and even failures.

It is worth to note based on the experts’ judgment and experiences in the fields, Thinlays are a pavement preservation tool and not a dense-graded material. It does have structural value, but it’s not to be used solely for a typical structural valued roadway. There is a case on a project that used Thinlay instead of a standard-thickness mat to widen a roadway to create turning lanes. The pavement quickly failed.

Lesson taken is that the underlying structure of the roadbed has to be sound for a thinlay to perform properly. For example, if there is block cracking, then a contractor has to crack seal the roadway or apply an underseal membrane on the material.

But because thinlays have had a high success rate in preserving roadways – and generally are thought to extend the life of a pavement for at least seven years – there is a rush to use this method outside of its intended application.

This is an ongoing battle for proper use, especially with some of the entities out there, because they see the value in it. It costs more per ton to produce and place, but a ton of it goes a long way, especially at less than an inch.

As a result, some agencies want to use it in all situations that call for a pavement preservation method. It is once again to note about a certain pavement condition not being the correct application for this product, and that the situation needs to be reevaluated.

Asphalt Pavement Method

The condition of a pavement is the first consideration when deciding to use a thinlay (see sidebar), but the main way to ensure long-term success is site preparation, which needs to be carefully planned and executed.

One of the biggest factors is cleanliness, particularly if any milling is involved. To do make sure the cleanliness, brooms can be used to. Sometimes, on one section of roadway, a water truck with a broom to clean is used. The reason is that the slightest amount dust, especially on trackless tack, the mat does not bond and slippage occurs.

It is worth to note that applying too much tack coat can cause other problems. In addition to that when milling it’s been effective to allow traffic to run on the milled surface a day before thinlay application. The reason is traffic helps remove the dust and it ensures that the surface is dry.

The Thinlay application itself contains a smaller nominal aggregate. The smaller nominal aggregate size used in thinlays presents a transport challenge for the mix, as it has a tendency to lose heat quickly. The insulated trucks are a must when hauling the mix, and placing tarps over the mix, particularly with distances of more than 25 miles from plant to job site.

When starting dealing with thinlay mixes and manipulating them, they can start to chunk. So when trying to lay a 1-inch mat, and these cold chunks come through, they get caught underneath the screed. In this situation there’s nothing can be done except stop the work, pick the screed up, and then start again.

This starting and stopping with a thinlay mix is problematic because it can take roughly 25 feet for the screed to level itself out, causing a shadowing effect.

Additional tips with a thinlay, it’s real important that once starting, It should be continued non-stop. The easiest way is simply to follow basic standard paving procedures.

Contact us

Phone Call |

Text Message |

|