Porous Asphalt Pavement Method

Conventionally, pavements are designed to let rainfall and runoff to flow along the pavement surface, draining into nearby catch basins and/or ditches of roads or parking lots. On the other hand, porous asphalt pavement is a type of type porous pavement structure specifically designed to allow rainfall and runoff to flow into and through the pavement structure. Porous pavement provides the potential to collect and/or slow the rate of run-off from other impervious surfaces.

Conventionally, pavements are designed to let rainfall and runoff to flow along the pavement surface, draining into nearby catch basins and/or ditches of roads or parking lots. On the other hand, porous asphalt pavement is a type of type porous pavement structure specifically designed to allow rainfall and runoff to flow into and through the pavement structure. Porous pavement provides the potential to collect and/or slow the rate of run-off from other impervious surfaces.

There are many benefits of this type of pavement. Porous asphalt used in place of traditional impervious paving materialsdecreases the total amount of runoff leaving a site, promotes infiltration of runoff into theground, decreases the number of pollutants carried to a storm drain or waterway,and aids with reducing peak runoff velocity and volume.

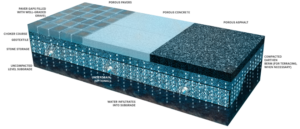

In term of construction, the design for application of porous asphalt consists of at least four layers, as follows.

- a twoto four-inch layer of asphalt

- a one to two-inch filter layer of half-inch crushedaggregate

- a 12-inch minimum reservoir layer of one to three-inch aggregate,and;

- a layer of geotextile material

Porous Asphalt

Porous asphalt consists of standard bituminousasphalt in which the fines have been screened and reduced, creating void space tomake it highly permeable to water. The void space of porous asphalt is approximately16%, as opposed to two to three percent for conventional asphalt.

Porous asphaltitself provides for some pretreatment of runoff. The crushed aggregate filter layeraids with pollutant removal and provides stability for the stone reservoir layer duringapplication of pavement. Treated runoff is stored in the reservoir bed, a highlypermeable layer of open-graded clean-washed aggregate with at least 40% voidspace.

Nonwoven geotextile material placed between the reservoir bed anduncompacted subsoil prevents the migration of fines into the stone reservoir, whichcould clog the system. The treated water then percolates through the uncompactedsoil base to recharge the groundwater supply.

Though this type of permeable paving materials has been in existencesince the 1970’s, their implementation has been slow. The reason is duepredominantly to unfamiliarity with correct procedure, leading tofaulty installation, and a subsequently high rate of failure. The good news is, with proper installation and maintenance, these systems canbe very effective and long-lasting.

Porous asphalt is appropriate to many uses, including parking lots, driveways,sidewalks, bike paths, playgrounds and tennis courts. Porousasphalt can have a minimum service life of 20 years with suitable maintenance,including regular vacuuming of the surface to prevent clogging by sediment,

Porous asphalt has another application apart from stormwater and greywater management purpose. Porous asphalt surface mixes are also used by highway engineers. Instead of putting it on a stone recharge bed, they use it as a thin surface layer on conventional highway pavements. Rainwater sinks directly into the surface and then hits the impermeable asphalt layer below forcing the water to drain off to the sides. Even in a driving rainstorm, splash and spray from trucks disappear. Visibility for drivers is so much better, and it most case crashes and fatalities can be greatly reduced. Although they are thin, these porous asphalt surfacings also improve water quality.

The benefits of porous asphalt pavements cover environmental and safety aspects including improved stormwater management, improved skid resistance, reduction of spray to drivers and pedestrians, as well as a potential for noise reduction.

Contact us

Phone Call |

Text Message |

|